|

|||

|

BioButanol |

|||

|

What is biobutanol?

Are you looking for a biobutanol consultant? Common questions: Who are the biobutanol producers? How is biobutanol produced-fermentation and pyrolysis? Has butanol fuel been tested in vehicles? What are the common feedstocks for butanol? What is the commercial timeline for biobutanol? Common facts: Biobutanol was first produced via fermentation a hundred years ago. Over 6.5 billion lbs of butanol are used yearly. Not all biobutanol molecules are same-isobutanol has different properties vs. n-butanol. Companies like Butamax, Gevo, Colbalt technologies, Cathay continue to raise millions in funding. Solar butanol fuel has been produced from CO2.

Introductory Video The following video presents an overview of biobutanol. Let us know your thoughts and comments.

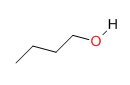

What is Biobutanol?

How is biobutanol made? Biobutanol is made via fermentation of biomasses from substrates ranging from corn grain, corn stovers and other feedstocks. Microbes, specifically of the Clostridium acetobutylicum, are introduced to the sugars produced from the biomass. These sugars are broken down into various alcohols, which include ethanol and butanol. Unfortunately, a rise in alcohol concentration causes the butanol to be toxic to the microorganisms, killing them off after a period of time. This made the fermentation process expensive and unrealistic when compared to the petroleum costs of the late 50’s. Luckily, new technological advances and the discovery of new microbes have improved the efficiency and cost of the fermentation process tremendously. Through genetic engineering, researchers have been able to modify the most efficient microbes to be able to withstand high alcohol concentrations. New modifications are constantly being researched, including the modification to enzymes and genes involved in butanol formation from biomass fermentation. A promising trend is a slew of recent ethanol fermentation plants purchases by biobutanol companies. These ethanol plants are being retrofitted with advanced separation systems to allow them to produce biobutanol. Since biobutanol has inherently higher value vs. bioethanol, the trend of the plant conversions is likely to continue. Aside from fermentation, a handful of companies are pursuing pyrolysis biobutanol. This route can convert waste biomass or crop waste into biobutanol. What are some recent developments for biobutanol? Aside from the increasing popularity of biobutanol due to its advantages, the percent yield and speed of its production are dependant partially on the organisms which process the substrates. Efforts are currently underway to improve the existing microbes used for fermentation. Next major cost hurdle is separation costs of butanol from fermentation broth--several membrane based separation methods are under investigation which can reduce costs of biobutanl by 40-50%. Through a mixture of genetic engineering and membrane separation, biobutanol has a promising future. Tags for quick search

Further Reading Huang, He, Hui Lui, and Yi-Ru Gan. "Genetic Modification of Critical Enzymes and Involved Genes in Butanol Biosynthesis from Biomass." Biotechnology Advances 471.1 (2010). Dürre, Peter. "Biobutanol: An Attractive Biofuel." Biotechnology Journal 2.12 (2007): 1525-534. | |||

|

|

|

|

|

|

|

|

|

"Biobutanol.com helped me learn about this exciting biobased

solvent. I look forward to formulating with it."

- Leonard Shine, USA - |