BioButanol

Feedstocks

What are the feedstocks for biobutanol?

Biobutanol can be prepared from any number of biomass feedstocks.

It is easier to produce biobutanol directly from a souce of sugar. However, a number of active

programs exist which will enable biobutanol production from crop wastes to energy grass. If you have

specific questions, please send me

details.

Do feedstocks for biobutanol compete with food?

Biobutanol can be produced from feedstocks which do not compete

with food. For example, efforts are on the way to covert algae biomass and waste wood particles to

biobutanol. See table below for several feedstocks which do not compete for food. Several of

these require only a 10th or 20th land resource of corn. In January 2011, U. of Alabama-Huntsville

report using Clostidium pasteurianum bacteria to ferment glycerol waste from biodiesel to produce

n-butanol. Additionally, a number of companies are focused on converting waste biomass from spoiled

foods or from food processing plants to produce n-butanol. A pilot plant currently takes sewage waste

and converts it to biobutanol at a New York waste water treatment facility.

Table: Feedstock and Biobutanol production - years to

commercialization

| Feedstock |

Fermentation |

Pyrolysis |

| Sugarcane Juice, Corn Kernels (Sugar source) |

0-2 years |

N/A |

| Sugar beet, Sorgum (complex sugar) |

0-2 years |

N/A |

| Miscanthus, Switchgrass (cellulosic

technology) |

2-4 years |

1-3 years |

| Wood waste, Crop waste, Poplar tree |

2-4 years |

1-3 years |

| Algae biomass |

2-4 years |

N/A |

| Food processing waste, household waste |

4-6 years |

1-3 years

|

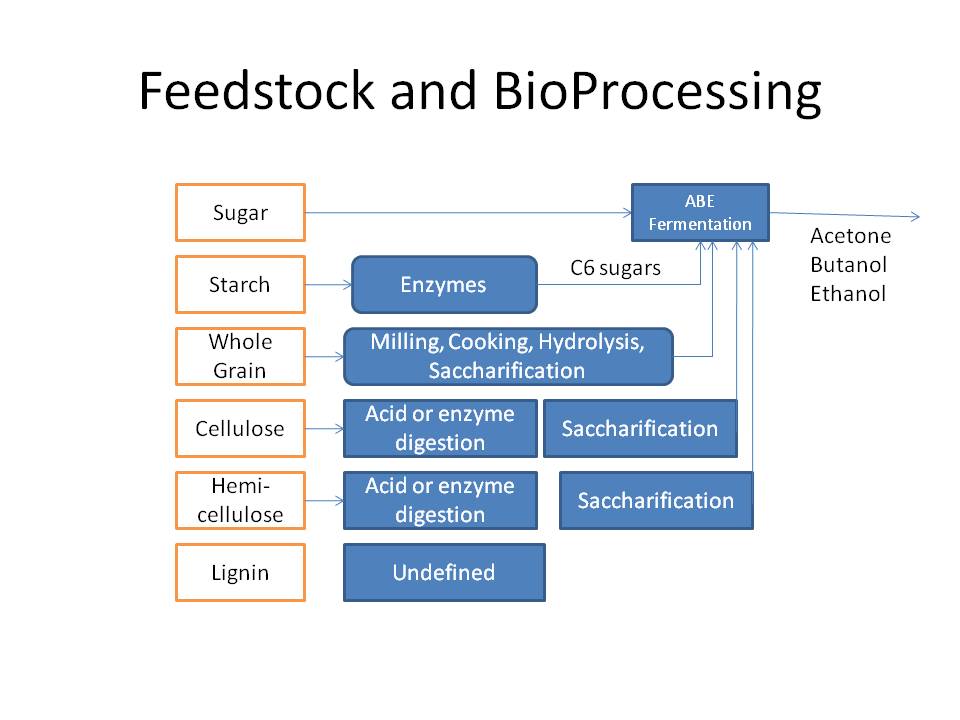

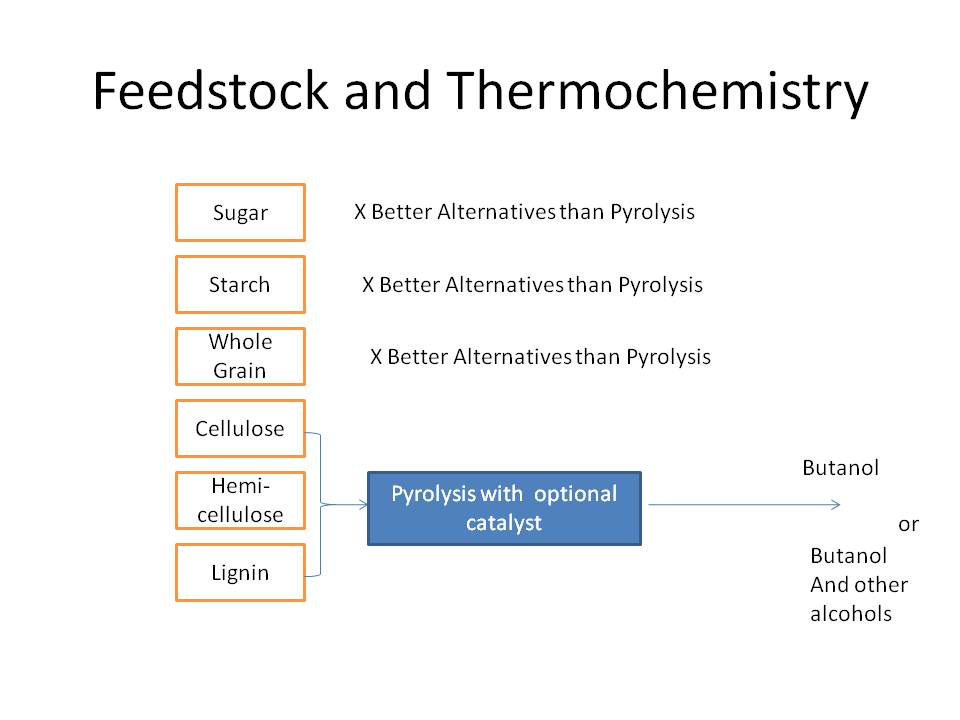

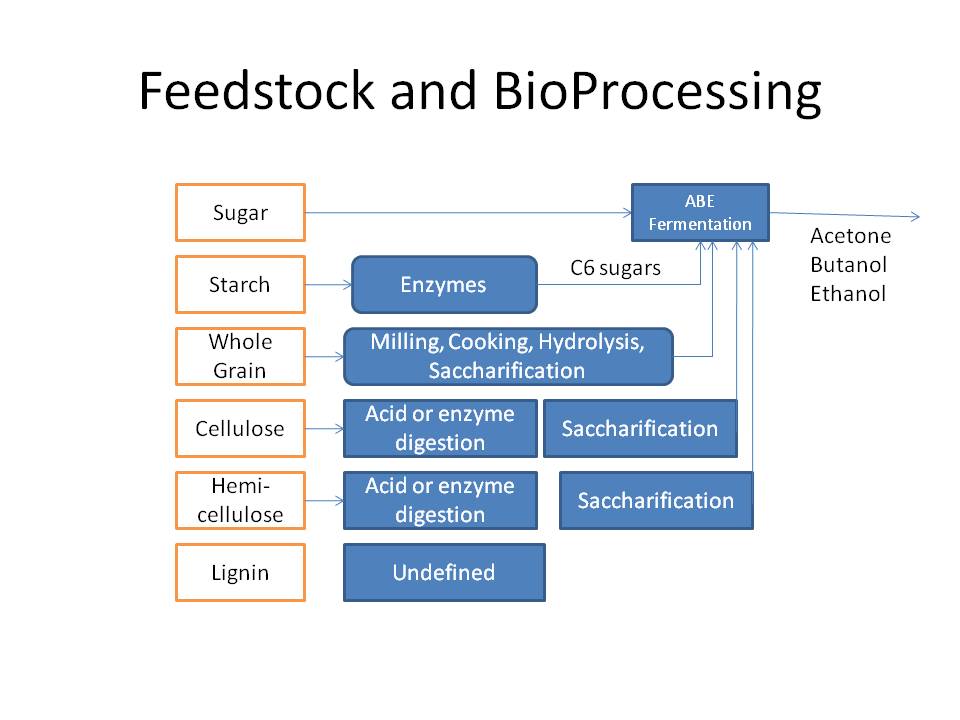

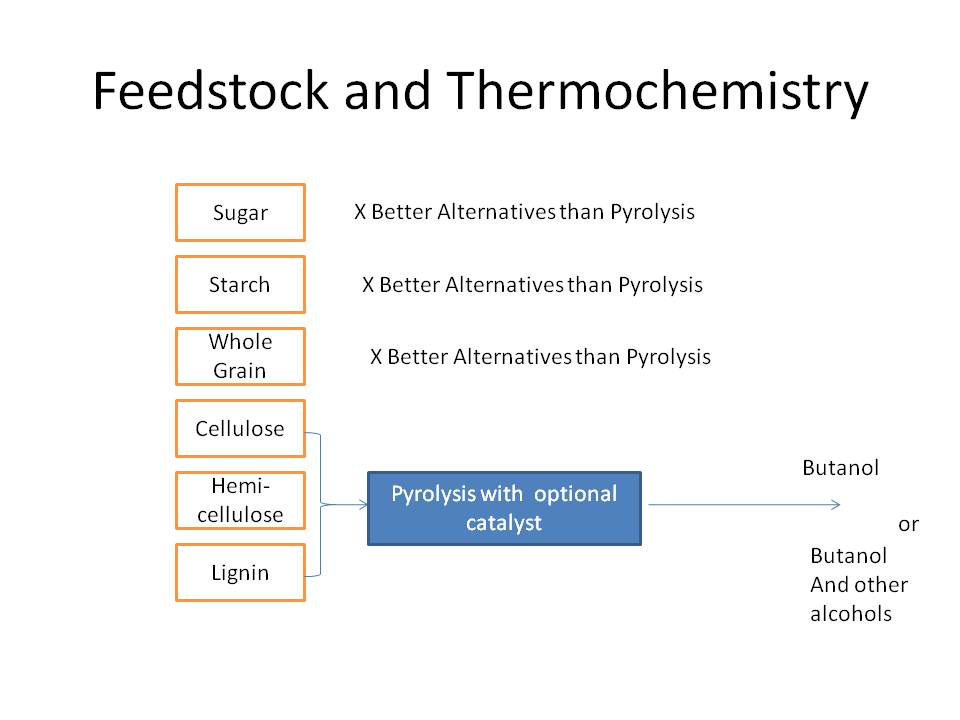

How is BioButanol produced?

There are two primary routes: fermentation and thermochemical

conversion.

As one can see, pyrolysis is a very forgiving process as no separation

or digestion step is needed. However, pyrolysis can have significant yield penalties.

|